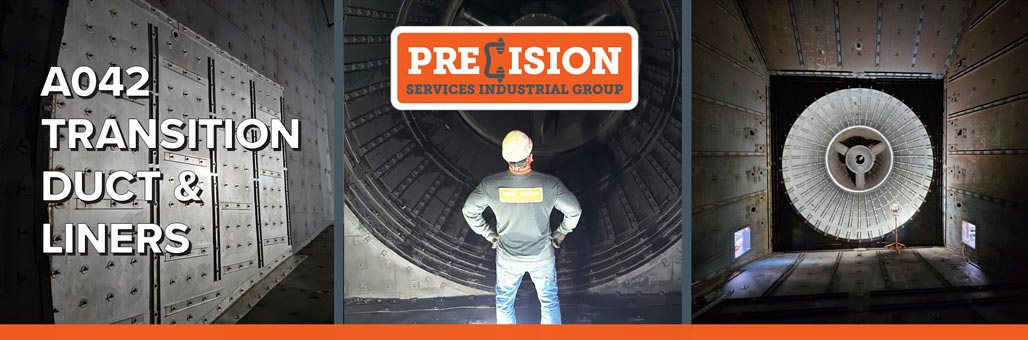

A042 TRANSITION DUCT & LINER REPAIRS

It is no surprise that equipment located near the turbine exhaust typically demands more frequent maintenance and repairs. The high operating temperatures up to 1200°F and gas flow causes wear on the material creating overheating issues that could lead to premature equipment failures or exhaust leaks. The A042 transition diffuser duct is an area that is typically exposed to these leaks and potential damage.

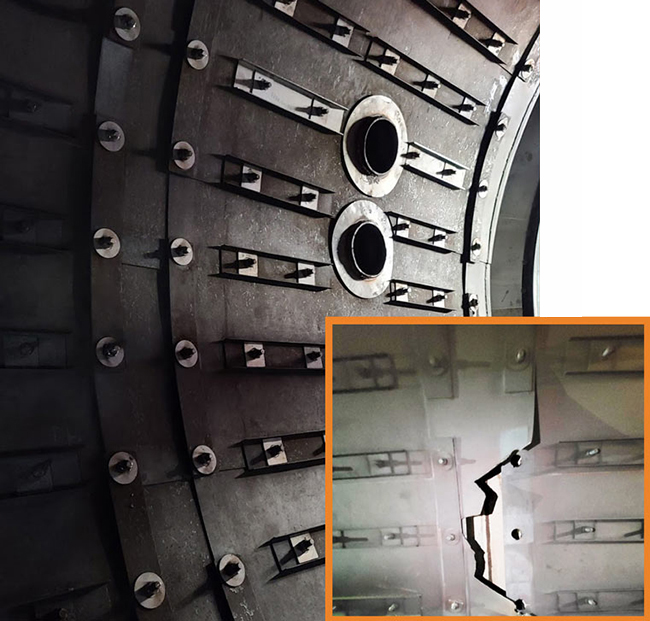

The A042 diffuser duct, located between the Flex Seal and the HRSG inlet, requires insulation covered by thin gauge stainless steel liner plates. Hundreds of studs are welded to scallop bars to secure the liner plates while allowing them to expand and contract during cycling. The scallop bars and studs are imbedded in dense high-temperature insulation for added protection.

Typical A042 diffuser duct damage:

- Loose or broken studs

- Scallop bars cracked or detached

- Liner plate distortion and fatigue cracks

- Insulation breakdown and voids

- External hot spots, flaking or missing paint

PSIG A042 transition duct & liner repair:

- Liner overlap is critical

- New scallop plates

- Repack insulation

- Insulation breakdown and voids

- New liners sandwich existing downstream liner

- New batten channels

PSIG Turnkey Services:

Comprised of experienced and professional specialists, technicians, supervisors, and managers, our service team has completed hundreds of A042 duct and liner repairs in addition inspections and complete turnkey installations.

- Thermal inspections and preventive maintenance assessments

- Initial dimensional measurements

- Complete installation and refurbishment

- Onsite repair – online and offline

- Mobile Production

- Emergency services

- Final inspection

- Priority on safety

Plant Inspections Include:

- HRSG Transition Duct/Liner Systems

- All Expansion Joints (Inlet, Turbine Exhaust, Stack)

- Penetration Seals

- A complete analysis of components’ current condition

- Photographs

- Thermography

- Maintenance recommendations

- Repair priority plan

Why Choose PSIG?

The PSIG team delivers proven and reliable solutions:

- Advanced proprietary designs & upgrades

- Innovative manufacturing

- Experienced & professional installation crews

- Meets tight scheduling requirements

- Safety First