GE 7FA FLEX SEAL UPGRADE

PSIG's Flex Seal Upgrade Effectively Mitigates OEM Leaf Seal Challenges

Located at the aft end of the exhaust manifold, leaf seals are overlapping sheets of thin-gauge Inconel and the only seal between the exhaust tunnel and the A042 transition diffuser duct. While not gas tight, in time, the combined high temperatures and the cycling of the gas turbine leads to leaks in the OEM seal which offer little flexibility and restrictive movement. When the leaf seals deteriorate, facility personnel and nearby equipment may become vulnerable to high-temperature exhaust gases, posing risks of injury and potential equipment damage.

PSIG’s Flex Seal Upgrade combines advanced design, materials, insulation, and fabrication to address the leaf seal challenges while providing a longer life cycle. Our team leverages decades of experience in turbine exhaust fabric expansion joint design, development, and repair to deliver the most reliable Flex Seal Upgrade solution available on the market today.

Benefits of PSIG Flex Seal Upgrades:

- New leaf seals, a fabric expansion joint cover, and strong insulation bolsters

- Gas tight barrier, during standard operation, and after leaf seals fail

- Heavy-duty flanges and bolt attachments

- Reinforcement against surges in back pressure

- Permanent manifold flange insulation

- A bolster with multiple layers of high-performance woven fiberglass cloth & Incoloy woven wire mesh reinforcement

- 12 – 15 years expected operating life cycle

PSIG Turnkey Services

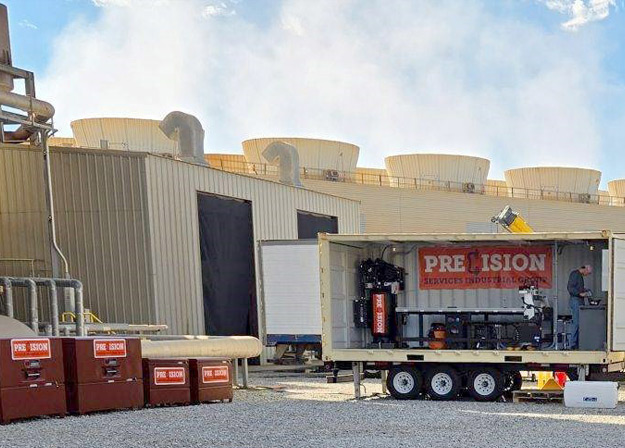

Our Flex Seal Upgrade is fabricated onsite and requires installation by our field service team. Comprised of experienced and professional specialists, technicians, supervisors, and managers, our team has installed hundreds of Flex Seal Upgrades in addition to completing inspections and repair services.

- Thermal inspections and preventive maintenance assessments

- Initial dimensional measurements

- Complete installation and refurbishment

- Onsite repair – online and offline

- Emergency services

- Final inspection

- Priority on safety

Plant Inspections Include:

- HRSG Transition Duct/Liner Systems

- All Expansion Joints (Inlet, Turbine Exhaust, Stack)

- Penetration Seals

- A complete analysis of components current condition

- Photographs

- Thermography

- Maintenance recommendations

- Repair priority plan

Why Choose PSIG?

The PSIG team delivers proven and reliable solutions:

- Advanced proprietary designs & upgrades

- Innovative manufacturing

- Experienced & professional installation crews

- Meets tight scheduling requirements

- Safety First